Rollers are widely used in various material handling machines. It may also be called as steel roller, rubber roller, aluminum roller, idler roller, driven roller, nip roller, steel drum, steel pulley, driven pulley, steel cylinder, tube, impact roller, converting roller, contact roller, pinch roll, heat rollers & chill rollers, pressure roll and dance rollers etc. The below are some industries that we served.

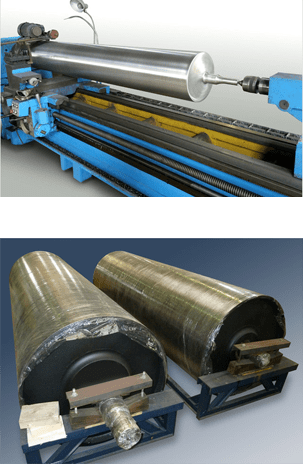

In the segment market of wide format precision rollers, we’re trying to be one of the best. Thank our customers, they are also urging us to keep improving continuously .

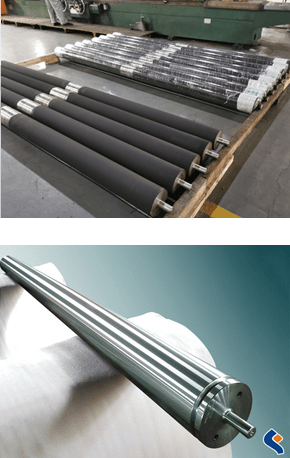

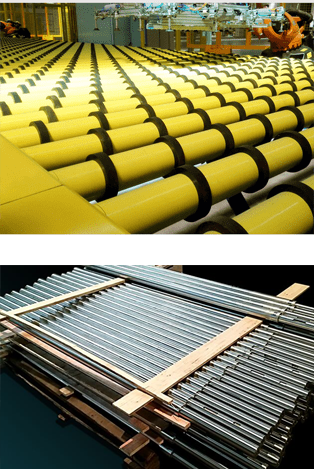

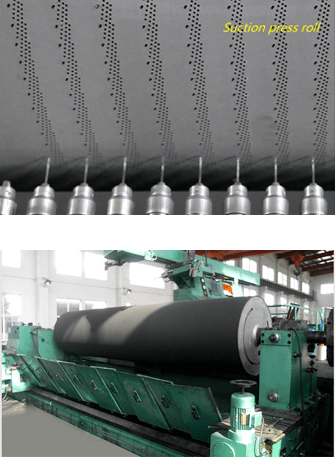

Steel rollers / EPDM rubber rollers / Aluminum nip rolls

NBR rubber rollers / Chrome driven shafts

(Trough idler roller for belt conveyor)

Do you still have questions about our processed products ?